2D plain panel fencing

Our product range includes complete fencing systems made of profiled or plain welded mesh panels. All panel versions come with installation posts and fastening accessories.

We manufacture gates and wickets on custom specifications. Our gates are available in double-leaf and sliding versions.

Application: Panel fencing is an enclosure solution with a great number of potential uses. Particularly recommended for securing: factory, warehouse, stadium, sports facility, school, public buildings, private properties.

Technical specifications

| Fence height [mm] |

Post height [mm] |

No. of fastening points per mid, end and corner post | Mesh size [mm] |

Wire dia. ø[mm] |

|---|---|---|---|---|

| 1030 | 1600 | 2 | 50×200 | 6×5×6 or 8×6×8 |

| 1230 | 1800 | 2 | ||

| 1430 | 2000 | 3 | ||

| 1630 | 2400 | 3 | ||

| 1830 | 2400 | 3 | ||

| 2030 | 2600 | 4 |

Finish

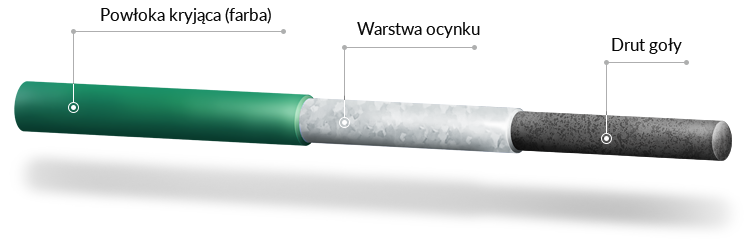

Our panel fencing solutions are made of galvanized steel wires that can be optionally powder coated, just like the fencing posts, and the powder coating colour is at customer's discretion.

Our fences and posts boast high strength, durability and corrosion resistance. The posts are delivered with PVC caps to seal off the top openings and prevent ingress of water.

Colours

Our standard powder coating colour palette includes: RAL 6005 (moss green), RAL 7016 (anthracite grey), RAL 8017 (chocolate brown), and RAL 9005 (jet black). We also provide selection of other colours from the RAL palette. Below is a presentation of the most popular panel colours chosen by our customers.

Installation method

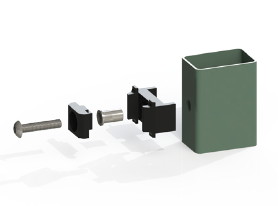

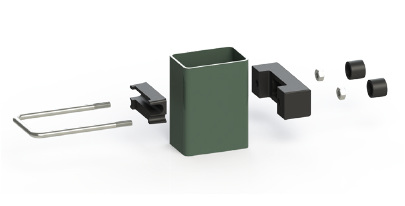

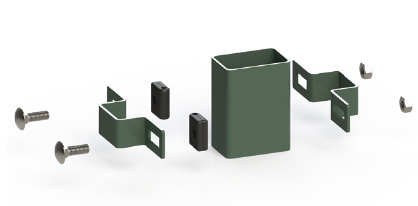

The fencing panels are very easy to install on fence posts: they are fastened with clamps that are adjustable to perfectly align all panels.

-

Hook screw

-

Plastic base

-

U-bolt

-

Clamp

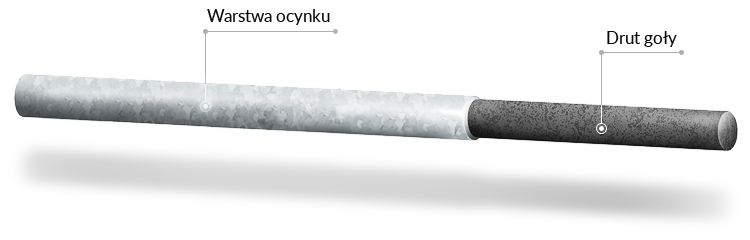

Galvanized and powder-coated

Up to 15 years of corrosion protection

Hot-dip galvanizing

Our fencing components are carefully cleaned in multiple stages and protected against corrosion by hot-dip galvanizing.

Hot-dip galvanizing is a process of coating pretreated parts by immersion in molten zinc held at 450-460°C. This deposition process forms a very strong intermolecular bond between Fe and Zn, which can provide corrosion protection that lasts as much as 50 years. An advantage of this process is the uniform deposition of galvanizing, and the galvanic coat reaches even the most difficult surfaces (e.g. grooves, bends, corners, etc.). The average thickness of a hot-dip galvanized coating is between 50 and 70 µm.

Extended resistance against corrosion, chemicals, high temperatures, and mechanical damage.

Galvanizing and powder coating

All fencing components are powder coated after galvanizing. Each buyer can choose a powder coating colour from the standard RAL palette.

The powder coating process done by depositing a coat of powdered paint with electrostatic spraying. The electrostatically charged powdered paint particles are deposited on the processed surface. Next, the deposited powder coat is cured in an oven held at 200°C, which produces a paint coat that resists corrosion, chemicals, high temperatures, and mechanical damage.